|

Finishing Technology’s Anodizing Capabilities

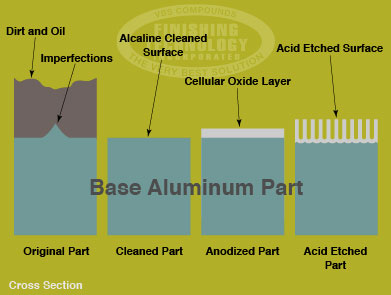

Acid Etch

Acid etch is the chemical process for removing the silicon rich surface of an aluminum die cast to helps produce a more uniform, leveled surface before subsequent chemical treatments like anodizing. During this process the surface imperfections such as extrusion lines and scratches are smoothed out, producing a more uniform appearance that can range from a bright, shiny aluminum surface to a more matte, satin finish. Acid etch is the chemical process for removing the silicon rich surface of an aluminum die cast to helps produce a more uniform, leveled surface before subsequent chemical treatments like anodizing. During this process the surface imperfections such as extrusion lines and scratches are smoothed out, producing a more uniform appearance that can range from a bright, shiny aluminum surface to a more matte, satin finish.

The Acid Etch process includes:

- An alkaline clean – especially if machining oil or other heavy soils are present

- Acid etch

- Hot deionized water rinse

- Drying

The benefits of Acid Etch include:

- Residue-free surface

- Minimized surface irregularities on hard-to-treat aluminum die castings

- More uniform appearance for greater aesthetic appeal

- Improved ability to accept anodize colors

- Increased the effectiveness of subsequent chemical treatments on the aluminum castings

Next: Considerations When Ordering Aluminum Anodizing from Finishing Technology

|

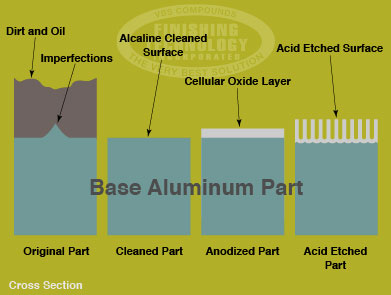

Protect your product while making it easier to work with.

Protect your product while making it easier to work with.  Acid etch is the chemical process for removing the silicon rich surface of an aluminum die cast to helps produce a more uniform, leveled surface before subsequent chemical treatments like anodizing. During this process the surface imperfections such as extrusion lines and scratches are smoothed out, producing a more uniform appearance that can range from a bright, shiny aluminum surface to a more matte, satin finish.

Acid etch is the chemical process for removing the silicon rich surface of an aluminum die cast to helps produce a more uniform, leveled surface before subsequent chemical treatments like anodizing. During this process the surface imperfections such as extrusion lines and scratches are smoothed out, producing a more uniform appearance that can range from a bright, shiny aluminum surface to a more matte, satin finish.