|

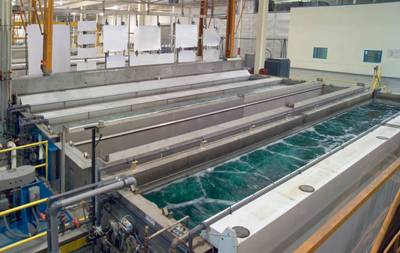

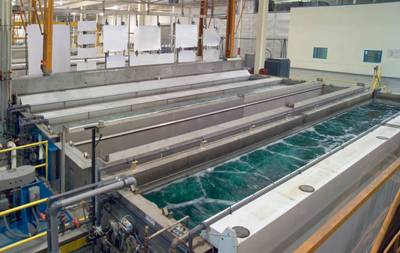

Anodizing has No Negative Environmental Impact

Anodizing is one of the more environmentally-friendly metal finishing processes. Anodizing is one of the more environmentally-friendly metal finishing processes.

As a water-based process, it uses no VOCs, there are no vehicle solvents, no carrier resins and any pigmentation used in anodizing is created by extremely small amounts of metals or dye securely locked within the hard surface. No halogenated hydrocarbons or similar toxic organics are used in anodizing.

Similar neutralization reduces most anodizing chemicals to common dissolved minerals. Most anodizing is performed without generation of hazardous waste, and in many cases aluminum-rich anodizing wastes are environmentally valuable in removing pollutants and settling solids in domestic sewage treatment processes.

The most common anodizing effluents, aluminum hydroxide and aluminum sulfate, are recycled for the manufacturing of alum, baking powder, cosmetics, newsprint and fertilizer or used by industrial wastewater treatment systems.

Anodized aluminum meets ELV, RoHS and WEEE directives.

Next: Finishing Technology’s Anodizing Capabilities Type 2

|

Anodizing is one of the more environmentally-friendly metal finishing processes.

Anodizing is one of the more environmentally-friendly metal finishing processes.